More resistant and durable

Our unique capabilities deliver flatter and fuller forged discs with top-notch mechanical properties. This makes them an ideal solution for high-wear applications such as mills, gear manufacturing, heat exchangers, mining equipment, and heavy machinery. Our forged discs are manufactured using state-of-the-art equipment and high-quality materials, ensuring strong, accurate, and reliable products.

MATERIAL |

RANGEO.D. up to 110 in |

WEIGHT RANGEUp to 55,000 lb |

BENEFITS

-

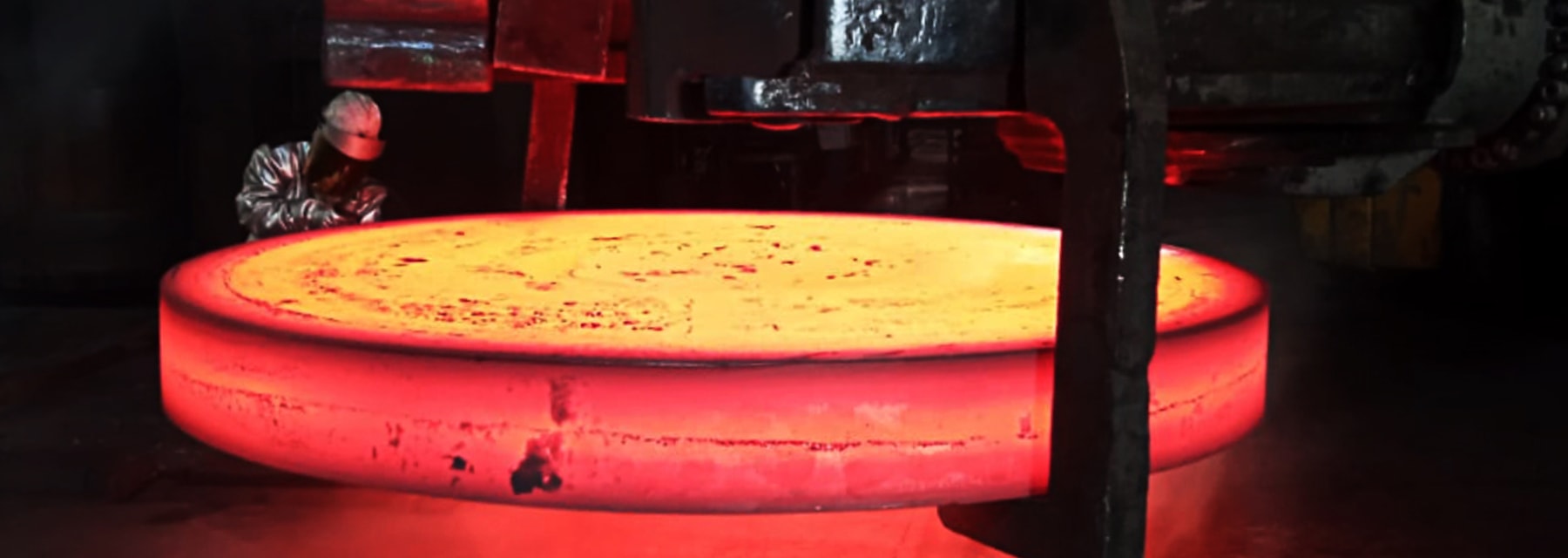

The forging process induces directional grain flow, improving the mechanical performance of our discs.

-

We can provide forged discs up to 106” outside diameter and 55,000 lbs in weight from a one-piece job to high-production runs.

-

At FRISA, we specialize in quick turnaround deliveries, product development, and expert guidance to reduce cost and machining time, while improving overall part and product performance.