An optimized power

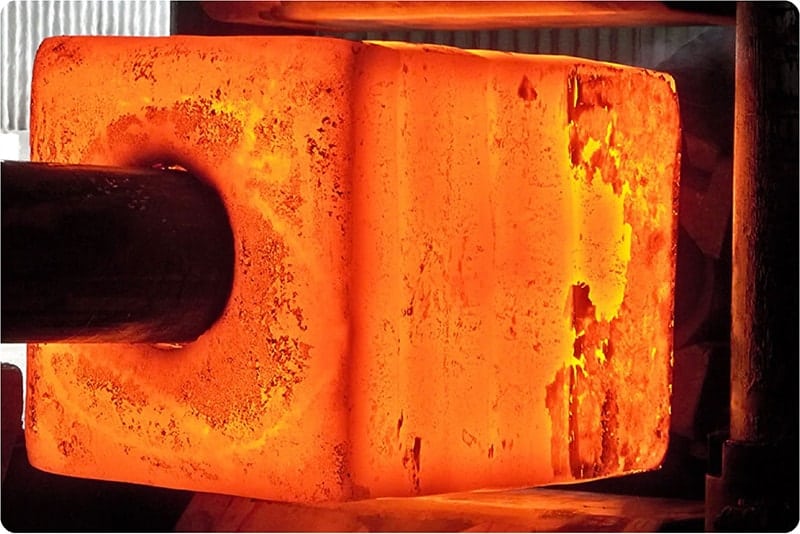

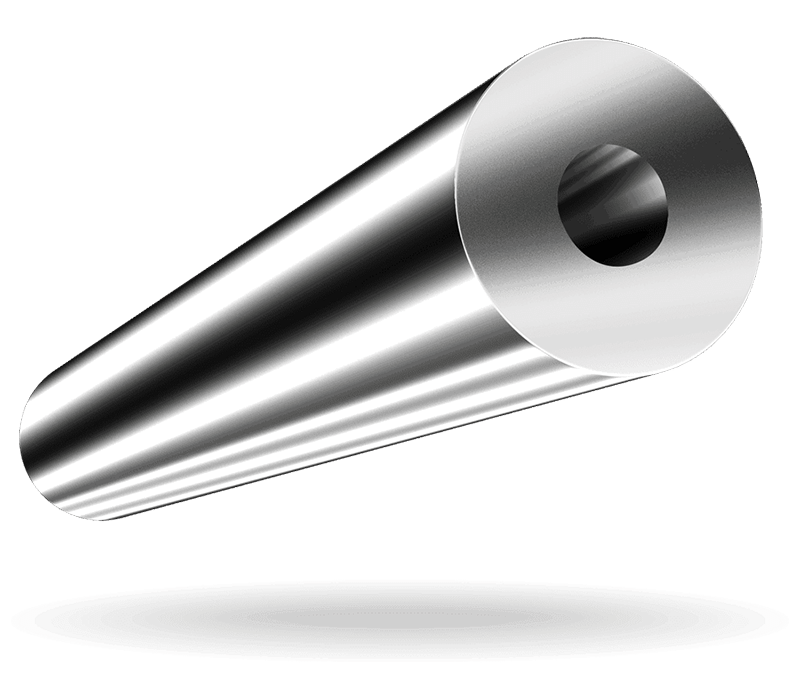

The inside diameter of our hollow bars is forged into the parts, not bored from solid bars, creating exceptional time reduction and effectiveness. Forging these parts as a single component allows us to guarantee high-quality strength. Plus, hollows provide a versatile and efficient solution for several construction and mechanical applications. Some of the product advantages include cutting waste and improved integrity.

MATERIAL |

RANGEO.D. up to 50 inI.D. up to 30 in |

WEIGHT RANGEUp to 55,000 lb |

BENEFITS

-

Our custom-made hollow forged bars are a higher quality substitute for heavy wall steel pipe and mechanical tubing.

-

They can replace centrifugal castings that often do not meet internal strength and integrity desired.

-

At FRISA, we can forge hollows with special configurations and geometries such as squares with a hole in the center, or hollows with different sizes on the outside diameter.